Select Your Region

Chemours Viton™ Fluoroelastomers

|

|

Introduced to the market in 1957, Viton™ Fluoroelastomers were designed to meet the demanding requirements for aerospace. Since its inception, Viton™ Fluoroelastomers offer new and innovative markets the same exceptional performance benefits that aerospace demands. Viton™ fluoroelastomers (FKM) provide excellent high temperature and chemical fluid resistance for sealing and fluid transport in aerospace, chemical manufacturing, renewable energy processors, electric vehicles (EV), internal combustion engines (ICE), oil and gas exploration, food manufacturing, and military.

Viton™ Fluoroelastomers - Unveiling the Power

| Viton™ Physical Benefits |

Viton™ Fluoroelastomers are designated by A, B, or F according to their resistance to corrosion from various chemicals or fluids.

- Temperature performance

- Viton™ vulcanizates retain good mechanical properties compared to other elastomers when exposed to extreme hot and cold temperatures. Compounds remain elastic indefinitely when they are exposed to oven aging up to 204ºC. When exposed to freezing temperatures, Viton™ offers satisfactory performance in dynamic applications where temperatures can be between –18 to –23°C.

- Excellent resistance to chemicals

- Just like the temperature performance, its resistance to degradation from harsh chemicals such as solvents, oils, mineral acids, lubricants, and fuels is proven compared to any non-fluorinated elastomer rubber

- Low permeability

- For a broad range of substances and gases, such as oxygenated automotive fuels

- Exceptional compression set and resistance to atmospheric oxidation, fungus, and mold

- Electrical properties

- Allows for decent dielectric strength in various voltage applications

- Low burning properties

| Viton™ Compared to Other Elastomers |

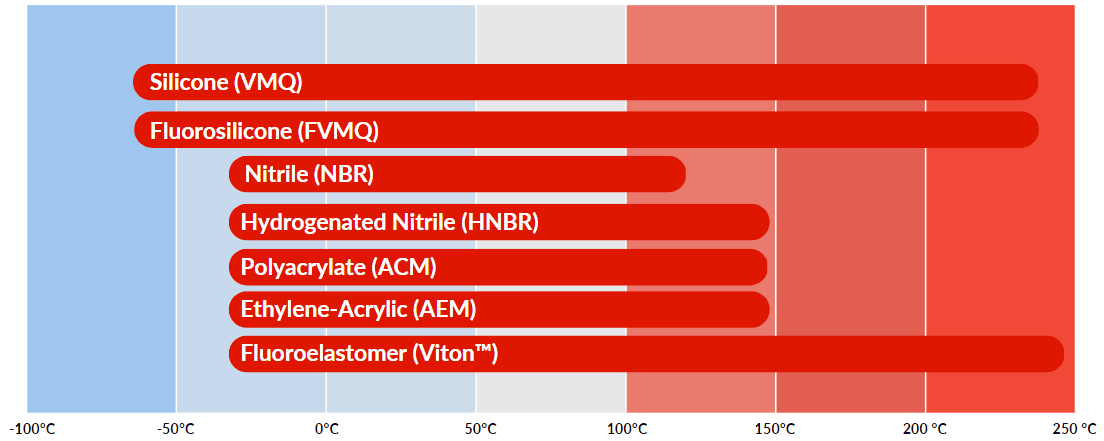

| Temperature Ranges of Various Elastomers Compared to Viton™ |

| Selecting Viton™ Fluoroelastomers |

With the differences in physical property characteristics, it's essential to understand the desired benefit needed for your application. If resistance to compression set is vital in a seal material application, one of the A-types of Viton™ would be the better starting point for your formulation requirements. For example, if chemical resistance from hydraulic fluids is the end industrial application, starting with the F-types of Viton™ would be the family to sample.

| Fluoroelastomer Content vs. Fluid Resistance and Low Temperature Flexibility |

| Standard Family Types | Specialty Types | |||||

|---|---|---|---|---|---|---|

| Viton™ A | Viton™ B | Viton™ F | Viton™ GLT-S | Viton™ GFLT-S | Viton™ ETP-S | |

| Nominal Polymer Fluorine Content, wt% | 66 | 68 | 70 | 64 | 67 | 67 |

| Percent Volume Change in Fuel C, 168 hr at 23°C* | 4 | 3 | 2 | 5 | 2 | 4 |

| Percent Volume Change in Methanol, 168 hr at 23°C* | 90 | 40 | 5 | 90 | 5 | 5 |

| Percent Volume Change in Methyl Ethyl Ketone, 168 hr at 23°C* | >200 | >200 | >200 | >200 | >200 | 19 |

| Percent Volume Change in 30% Potassium Hydroxide, 168 hr at 70°C* | (Samples too swollen and degraded to test) | 14 | ||||

| Low Temperature Flexibility, TR-10, 10°C | -17 | -13 | -6 | -30 | -24 | -12 |

*These are nominal values that are from testing standard results from a 30 phr MT (N990) carbon black-filled, 75 durometer vulcanizate. These results are not intended to service specifications.

If you are interested in exploring your potential Viton™ solution, click the link below and choose your desired product.

Viton™ fluoroelastomers and any associated logo is a trademark or copyright of THE CHEMOURS COMPANY FC, LLC used with consent by ChemPoint, an authorized distributor of THE CHEMOURS COMPANY FC, LLC.

Thank you

Thank you for your inquiry and interest in ChemPoint.

We will respond to you shortly.

ChemPoint will not under any circumstances release personal user information to individuals or companies. All information collection is solely used to support ChemPoint customers service communications. Read our Privacy Notice.

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Canada