Select Your Region

Superior Surfactants for Inkjet Inks

|

One of the most important functions of ink is to convey information on the surface it is applied. This information may be content, branding, or design, as in the case of packaging or literature. In other instances, inks provide identification for products or protect against counterfeiting. |

Achieve Superior Wetting and Leveling with Capstone™ Surfactants

When an ink requires better wetting to low–surface energy substrates, additives like surfactants are used to decrease the surface tension such that it evenly spreads and wets onto the substrate. However, if the substrate has particularly low surface energy, as polyolefins and PTFE do, some surfactants may not decrease surface tension enough, as shown in the left side of the figure below.

|

Capstone™ fluorosurfactants are the most effective additives at reducing surface tension, providing high wetting power, and facilitating good leveling on substrates. In many cases, Capstone™ can reduce the surface tension of water-based ink formulations to as low as 18 dynes/cm at extremely low use rates. Below is a chart illustrating various Capstone™ surfactant grades and their strong surface-tension reduction in deionized water.

|

In comparison, other commonly used surfactants in inks, such as hydrocarbon and silicone surfactants, only reduce surface tension to as low as ~30 dynes/cm and ~25 dynes/cm, respectively.

The significant reduction in surface tension that Capstone™ provides also promotes better leveling on substrates, where the better wetting and spreading ability reduces the incidence of surface defects, such as orange peel, cratering, pinoles, and fisheyes, that result from differences in local surface tension across the printed surface.

Reduce Ink Formulation Costs with Capstone™ Surfactants

If ink formulators are looking to make their products more cost-effective without compromising performance, Capstone™ can provide a solution by being used in conjunction with conventional ink surfactants. Here, Capstone™ reduces surface tension while decreasing the amount of surfactant used in the ink. Below is a graph comparing the use of Capstone™ versus a hydrocarbon surfactant, where both are blended with several ink surfactants. Since only a small amount of Capstone™ drastically reduces the surface tension in the formulation, less surfactant is required to achieve the desired surface-tension level in ink.

|

In addition to the above, certain Capstone™ grades can replace other additives in inks, like pigment-wetting agents and defoamers. Capstone™ may be added to the grind phase during ink production to provide excellent dispersion of pigments in ink systems by reducing the surface tension between solid pigment particles and breaking pigment agglomerates. Also, since Capstone™ is so effective at low use rates to accomplish wetting, it generates much less foam. This means Capstone™ can potentially eliminate the use of defoaming additives, depending on the application.

Increase Inkjet Ink Resiliency with Capstone™ Surfactants

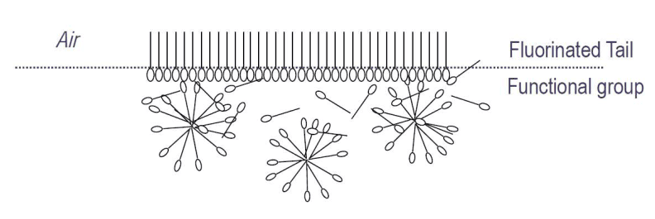

Capstone™ fluorosurfactants not only provide superior wetting and leveling properties but also increase the durability of the ink systems they are added to by enhancing antiblocking properties and resistance to water and oil. The fluorocarbon chains in Capstone™ surfactants are highly hydrophobic and lipophobic. When dispersed in water-based ink, Capstone™ surfactants orient themselves, as shown in the picture below.

|

The fluorinated chains, or tails of the surfactant, cure on the surface of the ink to create water repellency and oil repellency. This property is useful to ensure that inks have better chemical longevity and do not get dissolved when exposed to water- or oil-based liquids. The image below shows a test with water and oil applied to one surface containing Capstone™ (FS) and one that did not. While both surfaces exhibited good water resistance, Capstone™ demonstrated improved oil repellency.

|

The same properties above contribute to the antiblocking benefits Capstone™ provides. The drive to reduce VOCs in modern ink formulations has increased the use of resins with lower glass transition temperatures (Tg) to facilitate easier coalescence. Since resins with lower Tg have higher tack, the addition of Capstone™ helps decrease blocking in inks.

Formulating Inks with Capstone™ Surfactants

Several grades of Capstone™ are recommended for inks that vary based on the desired properties of each ink formulation. Capstone™ surfactants contain both nonionic and anionic options and offer versatility in being useful for water-based and solvent-based solutions. The slight chemical differences between these grades make some Capstone™ surfactants better at optimizing specific properties described in previous sections, but all grades generally enhance all properties. The table below outlines these recommendations.

| Capstone™ Grade | Ionic Character | Ink Type | Properties Optimized |

| FS-30 | Nonionic | Water-based | Wetting, leveling |

| FS-31 | Nonionic | Water-based | Wetting, leveling |

| FS-34 | Nonionic | Water-based | Leveling, wetting |

| FS-35 | Nonionic | Water-based | Leveling, wetting |

| FS-61 | Anionic | Water-based | Antiblocking, leveling |

| FS-65 | Nonionic | Water-based | Antiblocking, leveling |

| FS-22 | Nonionic | Nonpolar solvent-based | Wetting, leveling |

| FS-3100 | Nonionic | Water-based or polar solvent-based | Wetting, leveling |

Summary

When inkjet inks are applied to low–surface energy substrates, challenges arise with wetting and leveling that can compromise printing definition and quality. Capstone™ fluorosurfactants are the highest-performing surfactants for lowering surface tension; in water-based ink solutions, they can reduce surface tension to as low as 18 dynes/cm. Capstone™ also provides cost benefits to formulations where it can be blended with an incumbent surfactant package to reduce overall surfactant usage. It may also reduce the requirements for other additives like defoamers and antiblocking agents in ink formulations. Click below to request more information on Capstone™ and obtain a sample today.

Get a Sample

PHONE 425.372.9464

Are you in the correct region?

We’ve detected that you are located in a different region than the region selected on the website. Would you like to change your region?

Current Region: English - Canada